Impressed Current Anodes

One type of anode used in cathodic protection systems is called an impressed current anode. A “rectifier,” an external power source, is used by an impressed current anode to create a high potential difference between the surface that has to be protected and the anode. Typically, graphite, silicon iron, titanium alloys, cast iron, and metals covered in platinum and niobium are used as anodes.

Because they are inert, impressed current anodes are less vulnerable to corrosion assault. The electric current that generates the cathodic protection for the structure comes from an external DC power source. Better outcomes are obtained with impressed current systems when a high current is needed for cathodic protection.

- Mixed Metal Oxide Titanium Tubular Anodes: MMO Titanium Tubular Anodes are manufactured using titanium, which meets ASTM B338 Grade 1 or Grade 2 standards, which has been coated with Mixed Metal Oxide coating. The coating consists of IrO2/Ta2O5 and is suitable for use in all cathodic protection applications. Because MMO anodes have an extremely low consumption rate, the titanium substrate remains constant throughout the design life of the anode. MMO/Ti Anodes can also be provided prepackaged in canisters.

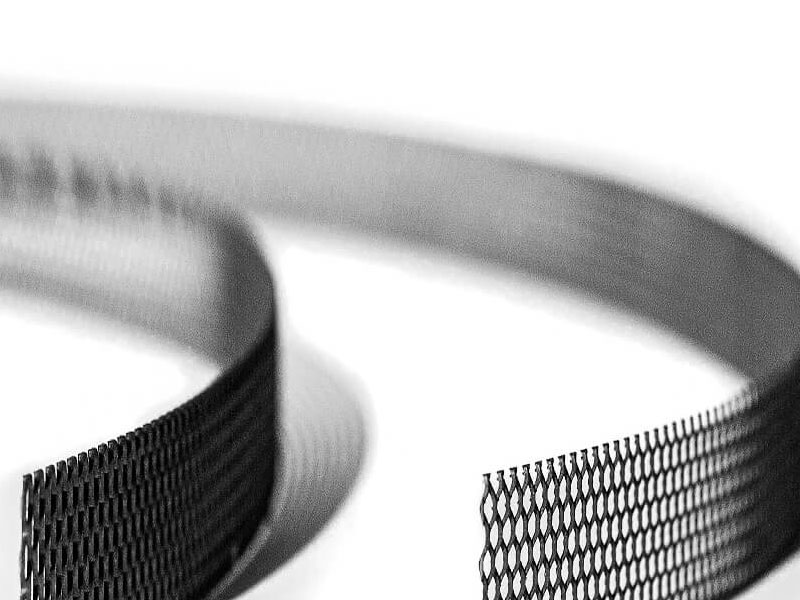

- Mixed Metal Oxide / Titanium Ribbon Anodes: MMO Ribbon Anodes Used In Fine Sand For Cathodic Protection Of Tank Bases. The anode is usually deployed in a Grid layout with Titanium Conductor Bars and Power Feed Connectors.

- Mixed Metal Oxide / Titanium Ribbon Mesh Anodes: MMO Ribbon Mesh Anodes are used for the protection of steel reinforcing re-bar embedded in concrete. A range of Ribbon Mesh sizes are available according to the desired current output / lifetime required. Anodes are thoroughly tested and proven for long life applications.

- Mixed Metal Oxide Flexible Linear Anodes: MMO Linear Anodes can be assembled using titanium Wire Anodes (ASTM B348), or Ribbon Anodes (ASTM B265) which have been coated with Mixed Metal Oxide Coating. The linear anode is packaged in a highly absorbent fabric sleeve. This sleeve is sewn using a double interlocking stitch, which prevents the seam from separating during installation, or when stored in high temperature conditions. The sleeve is filled using a high quality, calcined petroleum coke. The overall assembly is protected by an interwoven plastic braid to ensure the long-term integrity of the product structure.

- Mixed Metal Oxide Wire Anode: MMO wire anode designed for Impressed Current Cathodic Protection systems of steel structures. The high purity Titanium metal substrate has proven chemical corrosion resistance, low system electrical resistance, and high mechanical integrity against breakage.

- Platinized Titanium anodes: P.T Anodes are manufactured from a commercially pure titanium substrate plated with a very thin coating of platinum. The titanium serves simply as the anode body and the conductor, the active anode element being the platinum coating.

- Silicon Iron Rod / Tubular Anodes: Si-Fe Anodes used to suit impressed current Cathodic Protection of pipelines, tanks, and marine structures. Resistance to corrosion from a wide range of corrosive environments has resulted in the extensive use of standard 14.5% silicon iron alloy with 4.5% added chrome.

- Suitable For: Deep ground beds, Shallow / Horizontal Groundbeds, Seawater or Brackish water.

- Standard Sizes of Anodes: 1.5″×60″ OR 2″×60″ OR 3″×60″.

- Cable: these cables are available upon request. (XLPE/PVC, HMWPE, PVDF/HMWPE, KYNAR).

Related Products

Impressed Current Anodes

Impressed Current Anodes One type of anode used in cathodic protection systems is called an impressed current anod

Welding Machines

Welding Machines The Spot Welding Kit, which enables rapid and simple connections between the MMO/Ti Ribbon anode

Junction Boxes

Junction Boxes Applications involving cathodic protection employ junction boxes. For Junction Boxes with Post and

Carbonaceous Backfill

Carbonaceous Backfill (Metallurgical) Our backfill is of the highest caliber, which is crucial for boosting CP Sys

Test Point

Test Point (Test Stations) Utilized in situations involving road crossings and cathodic protection monitoring. It

Insulating joints

Insulating joints We provide linear expansion joints, PE steel transitions, and monolithic insulating joints. The

Electronic Decoupling Devices (PCR)

Electronic Decoupling Devices (PCR) EDD designed as a polarization cell replacement (PCR). The EDD is a solid-stat

Anti-fouling Systems

Anti-fouling Systems Utilized to cost-effectively prevent biofouling of interior pipework and strainers in cooling

Transformer Rectifiers

Transformer Rectifiers (Air Cooled / Oil Cooled) The most basic type of cooling system is an oil-cooled transforme

Solar Energy

Solar Energy The DC Output, battery bank autonomy, and location specifications supplied by the customer are taken

Sacrificial Anodes

Sacrificial Anodes (Galvanic Systems) A galvanic cathodic protection system, which shields submerged or buried met

Anode Accessories

Anode Accessories The power feed connector is one of the many anode accessories that can be utilized for power fee